News

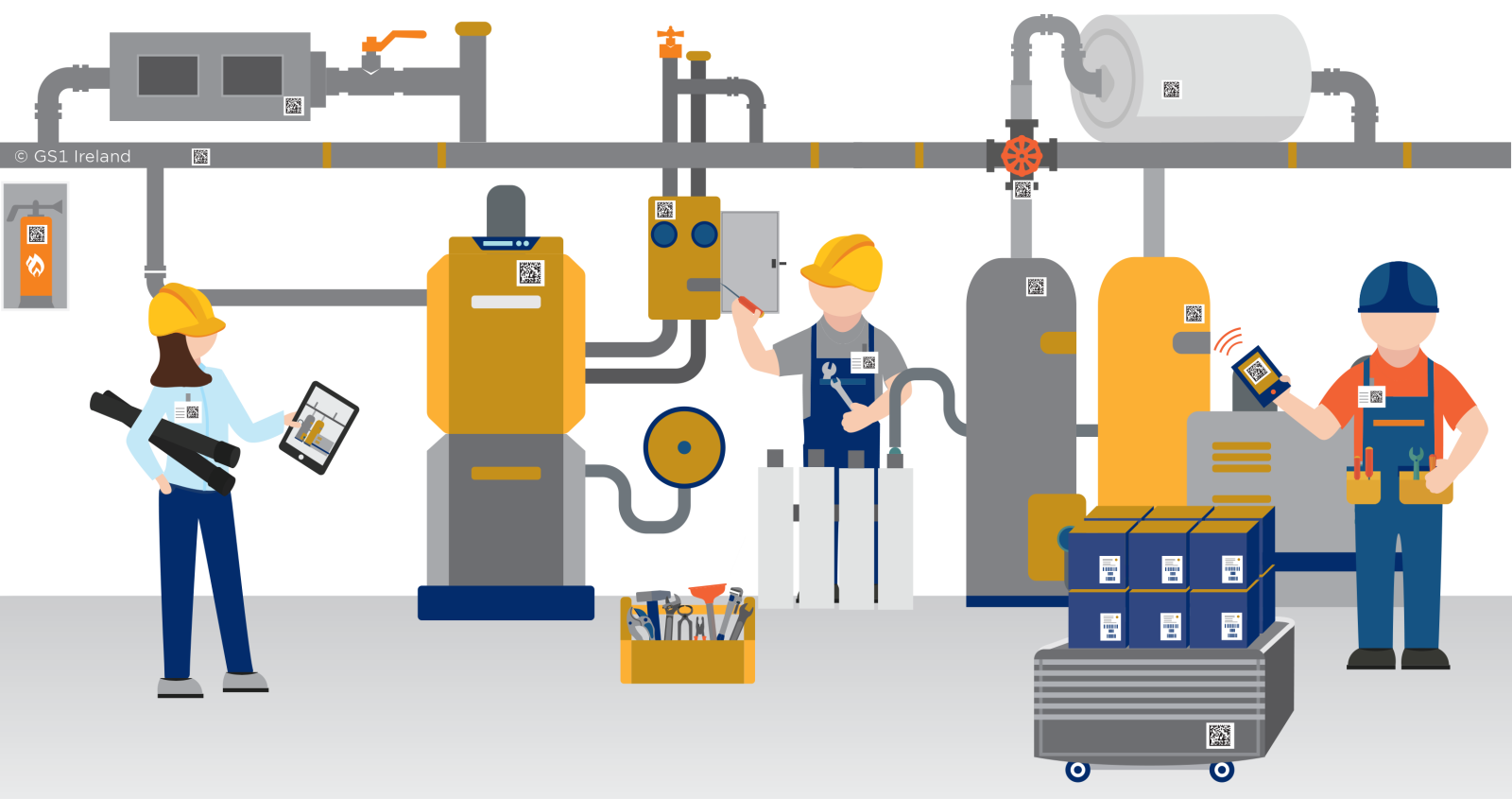

GS1 identifiers create a globally unique identity for products, assets, people, locations, and service relationships. Right from the early stages of a building’s design, architects and engineers can identify the products and parts that meet their specifications, including their environmental and operational cost attributes, and track their delivery on site. During installation and commissioning on-going verifications can occur, validating that the materials and assets installed meet the requirements specified in the Risk Assessment Method Statements and in the Health and Safety file.

Maintenance and facilities management teams also benefit greatly from the implementation of GS1 standards with digital links created between personnel, their qualifications, job tickets and schedules. For example, a GLN – Global Location Identifier - barcoded identification tag can be affixed to a door frame to identify a Plantroom. With a simple scan, service engineer can access all open work orders within the space and identify what needs immediate attention. Using a handheld device, the engineer can view a BIM generated image highlighting the affected assets and access a whole array of relevant data, such as service history, extracts from the Operations and Maintenance manuals and latest manufacturers bulletins. All key data related to the job such as the engineer's ID number, and the date and time can be automatically logged in the Integrated Work Management System.

Watch the video below to see how GS1 Standards and asset tags can help data capture and sharing in plantroom setting.

Building a complete digital portfolio of all assets, their maintenance history and open service jobs helps fulfil automated and just-in-time delivery of new and replacement parts to specific locations further saving on time and cost. Details of all the items in a delivery can be accessed by scanning the barcode on the tote box.

Digital connectivity can also connect the Facilities Managers with the manufacturers and suppliers of assets, parts, and materials, enabling service engineers to access product bulletins, recall alerts, and report back product issues encountered in real time. This enables manufacturers to readily respond to issues and assist Facilities Managers with replacing or fixing damaged product. Furthermore, Quality Assurance and R&D departments benefit from the product-specific detailed feedback as they strive to develop their products further.

The adoption of automatic identification and data capture (AIDC) solutions – such as the scanning of locations, assets, service personnel and work activity creates a real-time digital picture of a building and its constituent materials and assets.

Fexillon recommends the incorporation of GS1 Standards and Identifiers in a Building Information Management strategy, which should be implemented from the very beginning of a building or infrastructure project. The use of GS1 Identifiers supports the information exchange process and promotes the sharing, analysis, and reuse of information by all stakeholders. The resulting benefits include construction and operational cost savings, reduction of risks, reworks, and waste, and, above all, it facilitates prolonging the useful life of assets and possible repurposing for a secondary life cycle.

Contact us to discuss how GS1 Standards can be used for your Asset Lifecycle Management,

Visit GS1 Ireland website to find out more about GS1 Standards and Identifiers.